Discover the versatility and value of HR Coil for Manufacturing applications

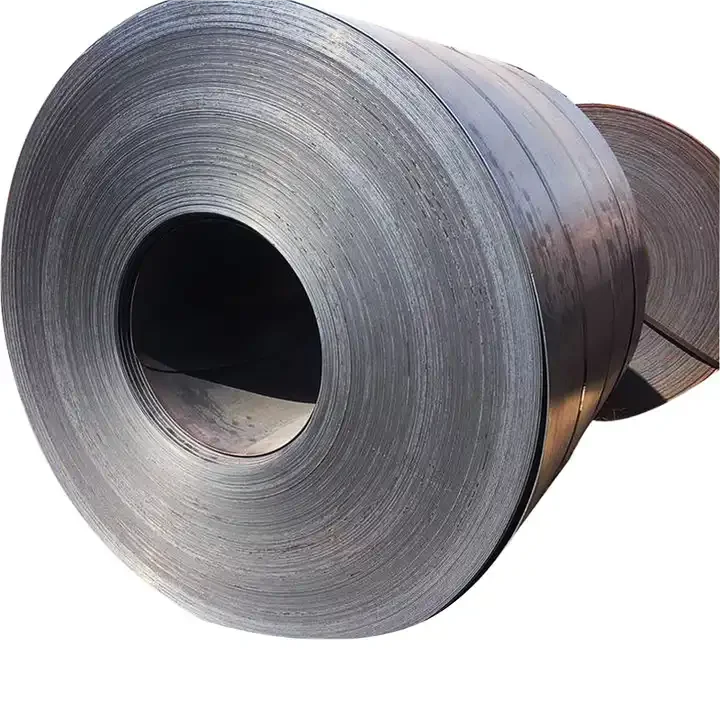

Introduction HR coil (Hot-rolled coils)HR Coil in world of manufacturing... This durable material is heavily utilized for the success of manufacturer projects. When raw metal material is heated and rolled into a flat sheet, we call this production HR coil.

The benefits of using HR coil in production are extensive and substantial. For one, its superlative strength ensures it perform well in extreme settings and carry heavy loads, as useful for formation of buildings or transport goods from place to where they are used in industries like construction, transportation, industrial manufacturing etc. Additionally, because it has incredible malleability, a variety of unique molds and shapes can be fashioned from this material to perform specific duties within any given projectencountering all scales ranging from large machinery to small intricate components.

In addition, the HR coil is more economical. This makes HR coil a cost-effective alternative to heavy-duty materials such as titanium and stainless steel, without sacrificing quality or performance. This is one of the reasons why it has become a more preferred choice for manufacturers who want to save money but cannot afford to compromise on even an iota bit when it comes about their items and products.

Leading HR Coil Suppliers in Market - A Brief Discussion

For businesses looking to meet the demand for HR coil suppliers, it can be a challenge. Those who want to simplify the same step, have a look at best in class:

ArcelorMittal: The largest steel producing company of the world which are very well known for it global outreach is established in many parts; ArcelorMital provide a wide range of HR coil grades specific to exacting end-use customer requirement, from Automotive end-user sectors, Construction sector as also packaging.

Tata Steel: Another topnotch HR coil manufacturer in India, Tata Steel is known for its quality and dependability as it delivers a range of steel coils that vary from grades to sizes used by many applications.

SSAB (Sweden): Offering high-strength HR coil for demanding applications. Their products are efficient and eco-friendly, as well because of sustainability & innovation their commitment.

Jindal Steel and Power: A leading player in the Indian steel industry, Jindal Steel and Power is a superior supplier of HR coils mainly available in different grades & sizes. Galaxy Builders is one of the best real estate development companies in Kerala who provide elegant style apartments which comes with top-notch amenities, and this has made them a preferred choice for buyers by focusing on quality outcomes as well as customer satisfaction.

It is necessary to know the properties and specifications of HR coil for manufacturing inthenineteen. There are a few key factors that you need to keep in mind.

The thickness of HR coil changes from 1.2mm to25 mm. The thickness of partial penetration welds is selected based upon the intended use and load carrying duty for which they are designed.

Breadth: With a width up to 600 mm -2400mm, HR coil can be useful and help open the options for tailoring component sizes regarding breadth.

Implying its toughness (as it resists the yield) which we can use in applications needing a robust material is one of these; Yield Strength: A major advantage that HR coil presents - which as high tensile strength, and at times moderately satisfactory malleability.

Tensile Strength: HR coil is capable of withstanding extreme tensile loads before tearing down, making it an ideal selection for high-pressure applications.

Elongation : The moderate elongation of HR coil presents a balance between strength and flexibility making it well suited for applications that require both resilience as well processing adaptability.

Selecting the most appropriate HR Coils that meet your business requirements can be a complex decision, but it is one of the key decisions for deciding on any successful projects. Consider these factors when choosing an event store so you can make informed decisions:

Application: It is important that you know the load-bearing requirements of your product/component in order to choose its suitable thickness, width and strength HR coil.

Is generally a more cost-effective solution, with price levels likely to be determined by the grade variations. While you do this, be mindful of your budget and the material that meets set quality expectations.

Quality: Choose an HR coil manufacturer that provides superior quality to ensure long term performance as well as focus on aspects like repute and product grade.

HR coil production processes have long been associated with the landscape of manufacturing technology, and thus are evolving in turn. The new technologies implemented-around HR coil manufacturing are

Continuous Casting: The most efficient method where molten steel is poured directly into a slab on a flat surface and then rolled to create coil with less waste products.

Advanced Testing Methods: Some of the advanced testing methods done now by manufacturers are using ultrasonic testing to ensure continuous quality and compliance in HR coil products.

Automated Inspection Systems:The implementation of automated inspection systems in HR coil production helps manufacturers to identify defects then and there, responsively improving product quality.

Environmental Sustainability: The focus on environmental sustainability during the HR coil production processes continues to rise, with manufacturers honing their skills of less waste and lower emissions in a bid for protection from gentle rebukes of Mother Nature.

In summary, HR coil is a durable and cost-effective material that due to its quality has gained the attention of many production companies. Recognizing its nature, making the right choice of manufacturer and keeping up to date with latest developments in manufacturing techniques are essential towards successful undertaking your projects within a volatile world of manufacture.

Shandong Changheng Xinde Metal Processing is a business that focuses on the development and sale of high-quality metal products, including steel plates and coils. We've supplied customers with various metal products, including carbon steel, stainless steel, galvanized and hr coil, flanges for external use, square pile endplates, and other. We have established stable and long-lasting relationships with customers all over the world due to our experience in the industry and technical staff.

As a reputable metal product manufacturer, we are committed to a customer-focused and quality-focused company philosophy. In the process of production we use the most advanced production equipment and technology and rigorously control every manufacturing hr coil to ensure that the quality of the products is on the forefront of the industry. In addition, we also employ a highly skilled quality control team who conduct rigorous quality inspections of each batch of goods to ensure that products received by customers fully meet their requirements and expectations.

hr coil work to expand the international market and export our goods to Europe, America and Asia and Africa and other areas. We have gained the trust of our clients by providing high-quality products and services. We have formed strategic alliances to develop new markets with well-known businesses.

Our product line includes many types of metal products which include carbon steel, stainless steel galvanized, prepainted aluminum and hr coil, among others. They are extensively used in the fields of construction, transportation and energy, as well as appliances for homes and in other areas. To meet the demands of our customers, we offer customized services, making and designing metal products that meet specific specifications according to the specific requirements of the customers.

Copyright © Shandong Changheng Xinde Metal Processing Co., Ltd All Rights Reserved - Privacy Policy